Imagine a bustling chemical plant where various substances flow through an intricate network of pipes. One day, due to a faulty valve, harmful chemicals from the facility contaminate the main water supply, burning the throats of those in the nearby community that drink the water and causing chemical burns to those who shower. This incident, caused by a backflow prevention assembly failure happened in Lacey’s Chapel, Alabama, on October 8, 1986. There have been many cases of backflow incidents in the past that have had serious repercussions. These types of incidents continue to happen today, causing contaminated water supplies, doing harm, and spreading illness. In this article, we will explore backflow, backflow testing, and the significance of calibrating Backflow Preventer Assembly Tester (BPAT) kits to maintain the safety of our water systems.

Understanding Backflow and Cross-Connections

Backflow occurs when the direction of water flow in a plumbing system reverses, potentially causing contaminants and pollutants to enter clean water supplies. Cross-connections are points where potable water interacts with non-potable sources and are common culprits for backflow incidents. Cross-connections can be found in commercial, industrial, and residential water plumbing systems as well as irrigation systems, fire sprinklers, restaurants, and recreational water facilities.

The Importance of Backflow Prevention

Backflow can lead to the infiltration of bacteria, chemicals, or other hazardous substances into our clean water. Protecting the public’s health and preventing water pollution requires effective backflow prevention measures. Critical locations in plumbing systems, such as cross-connections, are fitted with equipment, such as backflow preventer assemblies to greatly reduce the occurrence of backflow incidents. There are many types of backflow preventers, but overall, their goal is to make sure that fluids in a system flow in their intended direction and that flow reversal does not occur.

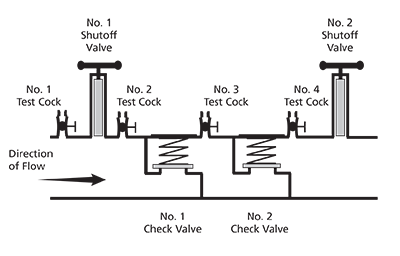

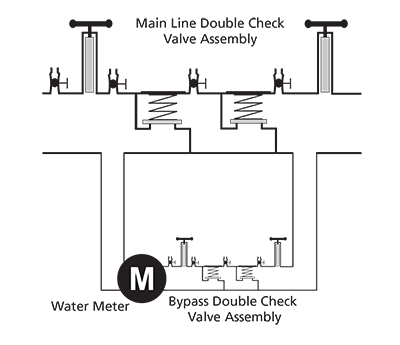

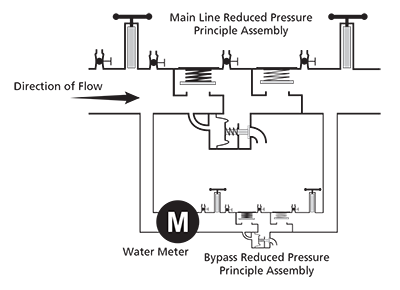

Brief Overview of Backflow Preventers

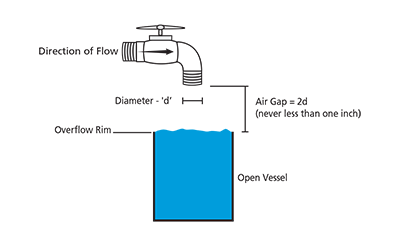

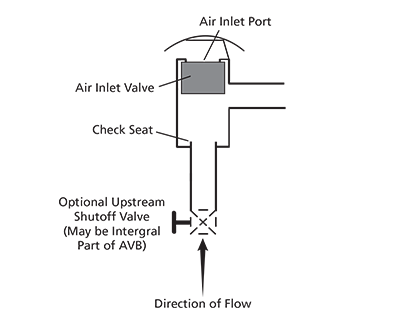

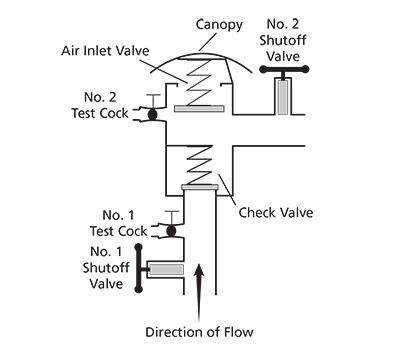

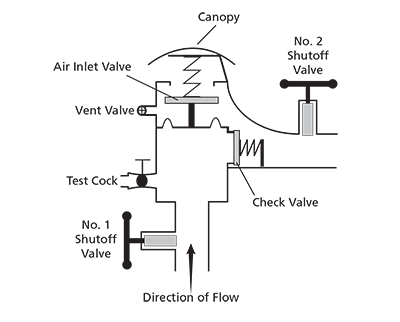

Backflow preventer assemblies are mechanical devices that guard against backflow occurrences. To preserve the integrity of the water flow, they use a mix of check valves, air gaps, and pressure differentials. Regular testing and maintenance of backflow preventer assemblies are crucial because these devices are mechanical and prone to failure and degradation over time.

Regulations Related to Backflow Testing

Regulatory agencies have set standards and laws for backflow prevention in order to help maintain clean, safe water. Standards for drinking water quality are defined nationally by the Safe Drinking Water Act (SDWA), which is enforced by the Environmental Protection Agency (EPA). To further safeguard the public water supply, the Texas Commission on Environmental Quality (TCEQ) has mandated cross-connection control and backflow prevention methods. In order to maintain compliance with regulations, routine testing of backflow assemblies by certified testers using registered Backflow Preventer Assembly Test kits (BPAT kits) is required.

Calibration, Maintenance, and Repair of BPAT Test Kits

Calibration is a critical aspect of ensuring the accuracy and reliability of BPAT kits. Proper calibration guarantees that test results are precise, minimizing the risk of false readings and potential backflow incidents. Regular calibration is necessary to maintain the integrity of the test kit’s components and to guarantee consistent performance. Indicators such as inconsistent readings or physical damage may indicate that a BPAT test kit requires calibration, maintenance and repair, or replacement.

Thermo-Temp BPAT Kit Calibration Services

When it comes to maintaining the accuracy of BPAT test kits, Thermo-Temp offers timely and reliable calibration services. With our expertise and commitment to precision, Thermo-Temp ensures that your BPAT test kits are accurately calibrated, allowing for dependable testing of backflow preventer assemblies. Our calibration services will give you peace of mind knowing that your BPAT kits are in compliance, providing accurate results and assisting in the prevention of backflow incidents.

Backflow prevention and testing play a crucial role in ensuring safe and clean water. By understanding the risks of backflow, the importance of backflow preventers, and the significance of calibrating backflow preventer assembly test kits, we can ensure safe, clean water for our communities and loved ones. Regular testing and maintenance are vital to identify any potential failures and prevent contamination and pollution incidents. Thermo-Temp’s BPAT kit calibration services offer a convenient, reliable solution to guarantee accurate test results, maintain legal compliance, and enhance the effectiveness of backflow prevention measures.