Imagine this scenario at a metal products manufacturer, fabricator, or machine shop somewhere in the Greater Houston area: Someone on the shop floor fumbles a tool and it hits the floor or another hard surface. This is a major issue for most users of calibration equipment, especially in manufacturing quality departments. They now must evaluate the instrument to make sure it still works and reads accurately. Unfortunately, some users of these handheld instruments will go about their day without reporting the damaged equipment. Your company could lose hundreds, thousands, or even millions of dollars depending on the use of the instrument.

Let’s take a quick look at how to handle damaged equipment. The safest course of action is to contact the Houston-area calibration experts at Thermo-Temp for their advice or assistance. This may include evaluating and recertifying the equipment. Forceful contact with the floor or any hard surface could damage sensitive equipment. The obvious signs of damage may include scratches, smalls nicks, or even dents.

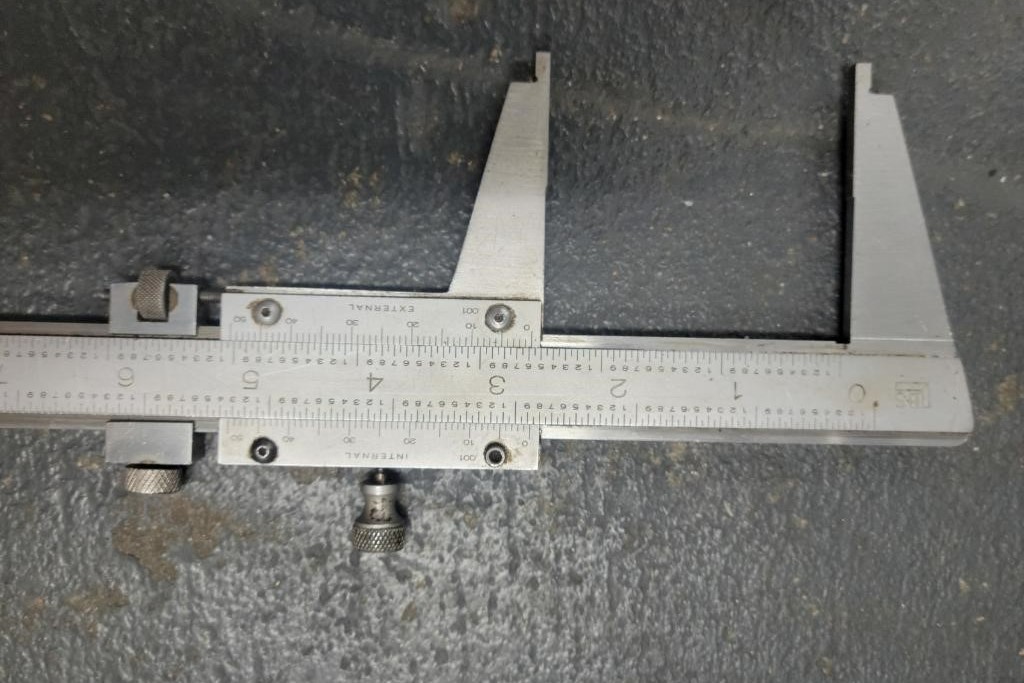

These superficial marks may not seem significant. In the case of a caliper, there are delicate internal components that you will not be able to see with the naked eye. The drop could cause a gear to jump or loosen the internal springs. This will lead to your measurements being drastically off. The caliper may now read 1/16th of an inch off the entire length of the caliper. While this may seem insignificant, when measuring accuracies down to 1/10th of an inch there is a greater chance of inaccurate measurements.

As a result, such inaccuracies could cause you to get to final inspection before finding out your measurements are wrong. Even worse, your client may call you to report the finding. Assuming no one says anything to you about the damage or issues an NCR (non-conformance report), the discovery may not happen until you send your caliper to Thermo-Temp when it comes due for calibration. Any parts or products that were inspected or calibrated with the damaged caliper will have to be recalled. That can incur substantial costs to your company.

It would be valuable to have a set of shop-grade gauge blocks on hand, which can be purchased from Thermo-Temp. Gauge blocks would be a quick remedy and will save you time and money while also providing peace of mind. However, the best course of action is to have the caliper inspected by a knowledgeable professional and repaired or replaced.