Introduction

Thermo-Temp, Inc. has partnered with our supplier Process Sensors Corporation to provide this overview of non-contact infrared temperature measurement, or pyrometry, for industrial process and research applications.

Industrial applications of pyrometers and thermal imaging systems for non-contact infrared radiation (IR) temperature measurement include:

| Industry | Temperature Measurement Examples |

|---|---|

| Cement and lime production | rotary kilns in all areas including material preheat, mid-kiln, burning zone, kiln shell, clinker cooler |

| Metals fabrication and manufacturing | pipe and tubing, forming and joining, forging, heat treating, wire and cable drawing processes, metal processing |

| Power | furnace exhaust in fossil fuel, biomass, and recovery industrial boilers |

| Semiconductor | rapid thermal processing (RTP), chemical vapor deposition (CVD), physical vapor deposition (PVD), silicon growth, silicon carbide susceptor, wafer polishing, wafer processing, epitaxy, etch |

| Steel | molten steel handling and casting, steel forming processes such as shear cutting, hot rolling, laminar cooling |

Thermo-Temp’s infrared temperature measurement experts provide product sales, installation and calibration of pyrometers and thermal imaging systems for all industries, research laboratories and applications requiring non-contact temperature measurement and control. Thermo-Temp offers complete solutions and services, including design, purchase, set-up, maintenance, and calibration of pyrometry and thermal imaging solutions.

Infrared Radiation Theory and the Application of Infrared Pyrometers

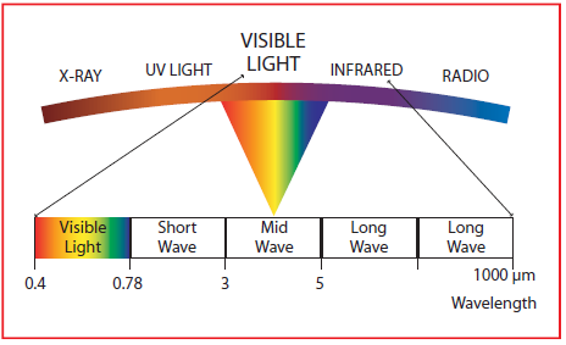

Infrared radiation (IR) is a component of the electromagnetic spectrum that falls between the frequencies of visible light radiation and radio waves.

Electromagnetic radiation is sinusoidal in nature (having a succession of waves or curves) and the components of the total spectrum are differentiated by the frequency bands they occupy.

IR occupies the wave band between 0.78 microns and 1000 microns, although IR sensors at a spectral wavelength of 0.65μ (visible light region) are also used to measure temperature. By focusing the IR energy radiated by a surface onto an IR sensitive detector, it is possible to determine the temperature of the surface by measuring the output from the detector. Though infrared radiation energy is invisible to the human eye, it is helpful to think of it as visible light because it behaves in an identical manner: it travels in straight lines, and can be reflected, absorbed and attenuated by objects and conditions in its path. The temperature of a glowing hot object (emitting in the visible region) can be determined visually based on its radiated color by a trained human eye.

Pyrometer Sighting Methods

To measure accurately, an IR pyrometer must be aimed at the surface or part of the surface of interest. For very large areas such as steel slabs or web processes this does not present a problem, but for smaller surfaces such as wire, pc board components, weld bead etc., a more precise aiming method is required.

Process Sensors’ pyrometers can incorporate a variety of sighting methods such as through-lens, where an installer can aim through the same lens that focuses the IR energy on the detector; or laser aiming via a built-in laser beam that illuminates the center of the target area. The pyrometers can also incorporate a video output that presents a picture of the area being measured on the image. A reticle defines the exact spot size of temperature measurement. Where there is no direct line-of-sight between the pyrometer and the target, a flexible fiber optic cable can be used to carry the IR energy around obstacles and corners. Specifically used in high-strength magnetic fields, high ambient temperature and vacuum environments, it allows the IR sensor’s electronics to be placed remotely, outside of these upsetting conditions.

Lenses and Fiber-Optic Cable

The infrared energy radiated by the target is transferred via focusable lenses either directly on the detector (standard version) or onto one end of a fiber optic cable. For applications where the lens must be refocused during operation, a remote focusable lens is available.

Focusing

Some pyrometers are designed with adjustable focusing. This does not necessarily mean that the target must be a sharp, clear image in order to obtain an accurate measurement, as would be the case with a camera. Pyrometer focusing is simply intended to permit the pyrometer to “see” the smallest spot size at a given distance. This is helpful when measuring through small openings or for avoiding obstacles in the sight path.

Sight Path

The sight path is the space between the pyrometer lens and the object being measured. For accurate measurement the sight path must be clear and free of obstacles, steam and water droplets, and heavy concentrations of particles. Devices such as fans and air purges, or careful sighting can usually ensure that this condition is met, but sometimes the use of a Two Color or ratio pyrometer can be helpful.

Focusing, Sight Path and Field of View

Unlike other temperature sensors, a well-designed infrared pyrometer is inherently a very accurate measurement device, but because it measures from a distance, the focus and field of view (FOV) play an important part in the quality of the measurement.

The FOV is an invisible cone that extends from the lens out to infinity. The FOV ratio is the diameter of the cone (Spot size) at a given distance from the lens. It is expressed in inches as a ratio e.g. 20:1, 60:1 etc. So if a 60:1 FOV pyrometer is focused at a distance of 120”, it will gather energy from a 2” dia. area on the object being measured. It will see only a small percentage of energy outside that circular FOV area based on the quality of its optics.

The equation to determine spot size is:

Focus Distance / FOV = Spot Size

To obtain an accurate temperature measurement, the FOV must be filled, smaller than the target at whatever distance the pyrometer is from the object being measured. The exception to this rule is the Two Color or Ratio Pyrometer which can measure accurately when only part of the FOV is filled. Listed below is an explanation of operation for one and two color pyrometry.

Single Color Thermometers

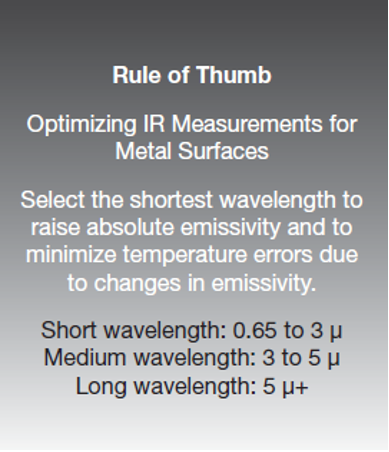

- Depend on the emissivity of the target:

- Short wavelength selection reduces the effect of emissivity errors for metals

- Offer a variety of wavelengths for specific applications.

- Used for low temperature measurements (subzero temperatures)

- Measure the average temperature within the field of view:

- Field of View must be completely filled by the target

- Focus dependent on the target

- Affected by dirty windows or dusty atmosphere

Two Color Thermometers

- Independent of emissivity of the target – (If emissivity changes proportionally, for each single color wavelength)

- Measure the weighted peak temperature within the field of view.

- Tolerates up to 99% blockage of the target

- Unaffected by dust and other contaminants in the field of view i.e. dirty viewing windows

- Unaffected by moving targets within the field of view

- Limited low temperature measurements to about 300° C

- Higher cost solution compared to Single-Color.

Ask Thermo-Temp About Your Non-Contact Infrared Temperature Measurement Application

The pyrometry and thermal imaging experts at Thermo-Temp are knowledgeable about non-contact infrared temperature measurement for a wide range of industries and applications. Thermo-Temp provides industry practitioners with the design, purchase, set-up, maintenance, and calibration of pyrometry and thermal imaging solutions. Call an expert at Thermo-Temp, Inc. with your IR temperature measurement and controls requirements or questions.

Thermo-Temp, Inc., and Process Sensors Corporation

Thermo-Temp, Inc. is the Texas distributor for Process Sensors Corporation equipment and service. For more information about Process Sensors pyrometers and thermal imaging systems and solutions, see this non-contact infrared temperature measurement product overview brochure from Process Sensors Corporation or visit www.ProcessSensorsIR.com.