Thermo-Temp, Inc. is pleased to announce it will represent IPS/Stanwood Corporation, provider of heat and corrosion resistant thermal processing fabrications and castings for the heat treating industry, and will offer heat treating equipment sales, consultation, and support for IPS/Stanwood customers in Texas, Louisiana, Oklahoma, and Arkansas. Thermo-Temp has taken over these responsibilities from Jack Kirsch (pictured above), former President of Systems I, Inc. and IPS/Stanwood’s long-time honorable representative in the region, who has retired. Jack selected Thermo-Temp because of their experience and expertise in the heat treating industry as well as their integrity and customer-oriented focus.

John Lehmann, Vice President of Operations for IPS/Stanwood, says, “We’re pleased to welcome Thermo-Temp to the IPS/Stanwood family as our outside Sales Representative for the States of Texas, Louisiana, Oklahoma, and Arkansas. Their experience with the heat treating industry and furnaces makes them the obvious choice for the job. We look forward to working with them.”

Jack Kirsch says, “I’ve known Chuck Osterhaus, CEO of Thermo-Temp, and the Thermo-Temp team for over 40 years and I am pleased to transition my IPS/Stanwood representation to them. They have extensive knowledge of heat treating processes and solutions and are well equipped to offer heat treating shops experienced consultation and support for their specialized requirements. I thought I would help IPS/Stanwood get someone trustworthy for this area and that’s why I selected Thermo-Temp. The services and industry experience that Thermo-Temp provides are even more valuable for the heat treating industry in today’s environment where finding skilled and experienced workforce is increasingly difficult.”

Chuck Osterhaus says “I appreciate Jack’s immense experience and successful career serving the heat treating industry for over 50 years and thank him for selecting Thermo-Temp on behalf of IPS/Stanwood for this region. Thermo-Temp’s experience enables us to understand and assist our clients with heat treating requirements, specifications, order placement, and support. We also provide consulting services and even have heat treating supervisory experience.”

IPS/Stanwood Thermal Processing Fabrications and Castings

IPS/Stanwood has served as a respected pioneer of the heat treating industry for over 70 years, offering custom-designed heat and corrosion resistant alloy fabrications and castings that are built to meet the demands of high temperature furnaces and corrosive environments. First founded in the 1940s, it started off fabricating products ranging from bar frame baskets utilized to anneal shell casings for the U.S. Military during World War II to donut machines, and today offers an abundance of products tailored to meet customers’ unique demands. Whether you are involved in basic metals production, heat treating, high temperature coating, or any business that requires fabrications used in carburizing, quenching, pickling, degreasing, and similar processes, IPS/Stanwood Corporation has the solution. Several of the products they offer as a full line manufacturer, which are available for purchase through Thermo-Temp, are outlined below.

IPS/Stanwood produces heat treating baskets of special size, style, or alloy, utilizing various welding methods such as mig (GMAW), resistance (ERW), and tig (GTAW) to accommodate diverse needs. It specializes in crafting customized solutions, readily offering design recommendations and accommodating unique requirements through consultation with Thermo-Temp and its experienced sales team.

IPS/Stanwood meticulously designs furnace fans and cast blades for optimal performance and quality, examining each fan casting for precision and balance in critical areas. Precision shaft machining utilizing nickel chrome alloy, state of the art welding techniques, and dynamic balancing utilizing advanced electronics and programming ensure long term integrity of their fans. They also offer cost-effective reconditioning options and maintain an inventory of common replacement parts to reduce lead times. The experts at Thermo-Temp can help clients assess if a fan can be reconditioned.

IPS/Stanwood has the solution for high alloy fabrication and fixture needs, including salt pot, muffle, centerpost fixture, corrugated box, serpentine tray, pressure welded grid or any other unique specialized fabrication. The company offers a wide variety of high quality cast alloy products. Castings include spider grids, reversible trays, centrifugally cast tubes, furnace replacement components, or custom fixtures.

The company offers a wide range of muffle styles and sizes for basic metals production, sintering, austempering, brazing or other thermal processing requirements. The muffles utilize a fully corrugated sheet of uniform material and are formed and assembled with a side weld (instead of a corner weld), which eliminates the high-stress concentration that often occurs with corner welding.

Radiant tubes manufactured by IPS/Stanwood utilize either all cast, all wrought, or a combination of both types of materials, and can be produced in all configurations. They are triple-checked to be gas-tight and with sound welds. The company offers straight tubes and return tubes in various configurations including U, S, P, and W bends.

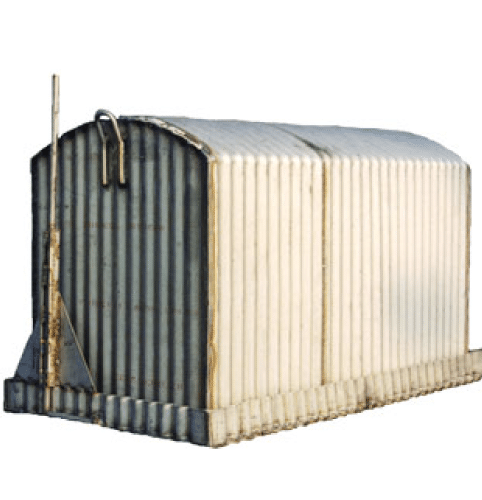

IPS/Stanwood produces strong and durable furnace retorts made with corrugated wall construction. They are stronger and more durable than retorts made with conventional straight-wall construction and will hold their shape through thousands of hours of service. The furnace and generator retorts may be made in many styles and are built to be gas-tight, strong, and to meet the most critical high temperature processing requirements.

The company also manufactures woven wire mesh products used for heat treating, plating, basic metals production, aerospace applications and other uses. Their wire mesh products are resistant to corrosion and wear and are woven using the highest quality wire, which is certified by their suppliers and further tested by IPS/Stanwood to confirm its material content and metallurgical characteristics.

Thermo-Temp’s skilled and experienced technicians in Houston, TX are prepared for the opportunity to serve IPS/Stanwood and businesses across the heat treating industry and they look forward to helping customers purchase and service any heat treating equipment that they need.

Please contact us to learn more about or purchase thermal processing solutions with IPS/Stanwood.