In the world of measurement and accuracy, one word stands out as the unsung hero: the calibrator. Whether you are an engineer, scientist, technician, or anyone dealing with measuring instruments, a properly utilized calibrator is your best friend. But what exactly are calibrators, and what do they do?

Thermo-Temp’s skilled calibration technicians are prepared to handle all of your calibration needs at our Houston calibration lab. In this article we highlight the essential role of calibrators, various types of calibrators, and how we utilize them to help ensure the accuracy of various instruments.

Calibrator Defined

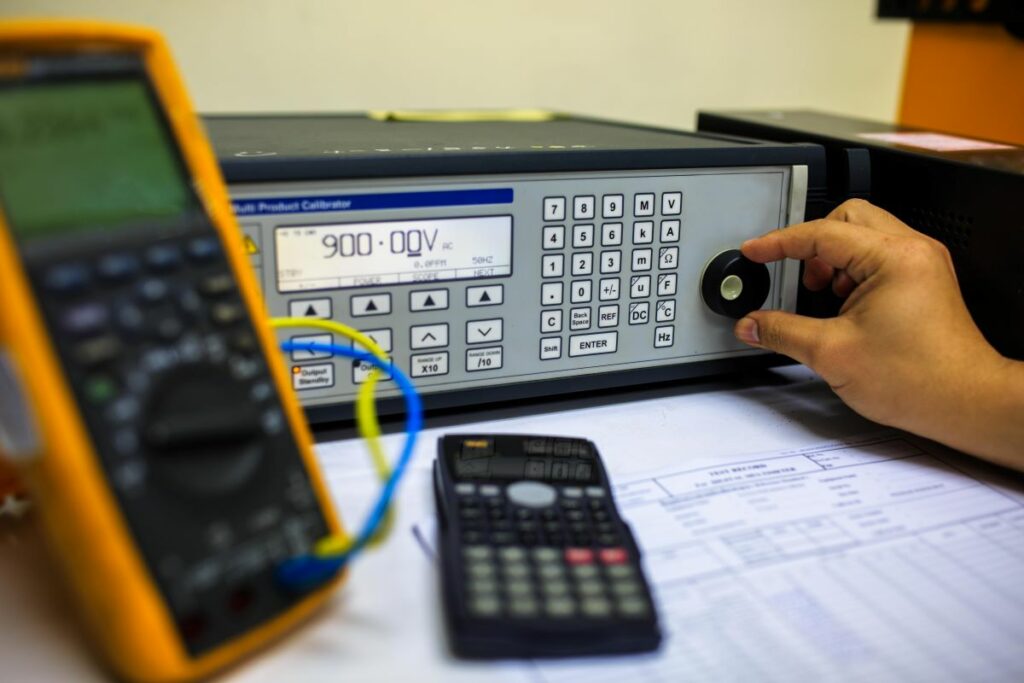

A calibrator is a device or instrument used to set, check, or adjust the accuracy and reliability of other measuring instruments. It serves as a reference standard to help maintain and improve the accuracy of instruments such as thermometers, pressure gauges, voltmeters, and more. Essentially, a calibrator utilized effectively by a skilled technician ensures that the measurements taken by these instruments are as accurate as possible.

The Role of a Calibrator

In the world of precision, calibrators and calibration technicians play a pivotal role in ensuring that measurements are accurate, reliable, and consistent. Without calibration, industries ranging from manufacturing and healthcare to aviation and research would struggle to achieve the high levels of accuracy they require.

- Accuracy Verification: The primary role of a calibrator is to verify the accuracy of other measuring instruments. Calibrators produce known values or signals, against which the instrument’s measurements can be compared. Any discrepancies are detected and addressed.

- Calibration Adjustments: If the instrument being tested displays inaccuracies, the calibrator can be used to adjust it. This process, known as calibration, ensures that the instrument provides accurate and reliable measurements.

- Consistency: Calibrators ensure that measuring instruments remain consistent over time. Regular calibration helps prevent drift or variations in readings, which is essential in industries where precision is paramount.

- Compliance and Certification: Many industries have stringent standards and regulations that require instruments to be calibrated regularly to maintain compliance. Calibrators play a pivotal role in meeting these requirements and obtaining certification.

- Cost Savings: Accurate measurements can save a considerable amount of money in the long run. By using a calibrator to maintain the accuracy of measuring instruments, industries can avoid costly errors and production defects.

Types of Calibrators

Calibrators come in various types and are designed to meet specific measurement needs. Some common types include:

- Electrical calibrators are designed to verify and adjust the accuracy of electrical measuring instruments. They generate precise electrical signals, typically in the form of voltage and current, to assess the performance of instruments like voltmeters, ammeters, multimeters, and oscilloscopes. Electrical calibrators ensure that these instruments provide accurate readings.

- Pressure calibrators are used to calibrate pressure measuring instruments, such as pressure gauges, transmitters, and sensors. These calibrators create known pressure conditions, either positive or negative, and compare the instrument’s readings with the expected values. Pressure calibrators help ensure that devices used in various industries, including manufacturing, petrochemical, and water accurately measure and control pressure.

- Temperature calibrators are essential for verifying and adjusting the accuracy of temperature measuring instruments. They come in various forms, including dry-well calibrators, liquid bath calibrators, and infrared calibrators, each suitable for different types of temperature sensors and probes. Temperature calibrators help maintain the precision of thermocouples, RTDs (Resistance Temperature Detectors), thermistors, and other temperature measurement devices.

- Flow calibrators are used to calibrate instruments that measure the flow of liquids or gases. They ensure that flow meters, flow sensors, and flow controllers provide accurate and consistent flow rate readings. Flow calibrators create controlled flow conditions to verify the performance of these instruments, which are widely used in applications such as process control, environmental monitoring, backflow prevention, and industrial automation.

- Dimensional calibrators are specialized tools used for verifying the accuracy of dimensional measurement instruments. They are employed to calibrate instruments like calipers, micrometers, and height gauges. Dimensional calibrators help maintain the accuracy of these devices, particularly in industries where accurate measurements of length, thickness, or diameter are essential.

- Mechanical calibrators are designed to assess and adjust the accuracy of mechanical measuring instruments. These calibrators are commonly used for instruments like torque wrenches, and dial indicators. They help ensure that mechanical devices used in manufacturing, construction, and automotive industries provide accurate measurements, which are critical for quality control and safety.

- Hardness calibrators are devices or standards used to calibrate and verify the accuracy of hardness testing equipment, such as hardness testers and durometers. Hardness testing is a common method for assessing the mechanical properties of materials by measuring their resistance to deformation when subjected to a specific force. Hardness calibrators help ensure the accuracy of hardness test results, which are important for determining a material’s suitability for various applications, including manufacturing and quality control.

- Mass/weight calibrators are devices or instruments used to calibrate and verify the accuracy of weighing scales, balances, load cells, and other weight-measuring equipment. Calibration in this context involves comparing the measurements made by the weighing instrument under test with known and traceable standard weights. The purpose of mass/weight calibrators is to ensure the precision and reliability of weight measurements in various applications, including scientific research, manufacturing, quality control, and trade.

Thermo-Temp sells many calibrator products and offers a variety of professional and certified calibration services. Contact our skilled calibration technicians and calibration lab in Houston, Texas for your calibration needs.